Structural insulated panels (SIPs)

Structural insulated panels (SIPs)

Structural Insulated Panel’s (SIP’s) are fast replacing traditional timber frames in garden room construction, but like timber frames come in different forms.

This build up is like you’d find used on the houses you see on shows like Grand Designs. Garden room suppliers who used this system buy their SIP’s from the same manufacturers as house builders.

What are SIPs?

Structural insulated panels (SIPs) are a high-performance building system for residential and light commercial construction. The panels consist of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB). SIPs are manufactured under factory controlled conditions and can be fabricated to fit nearly any building design. The result is a building system that is extremely strong, energy-efficient and cost-effective.

Exepectional R-Values

Once installed, SIP panels deliver unrivaled insulation and airtightness, which reduces energy costs over the building’s lifetime. SIPs are known to be about 50% more energy-efficient than traditional timber framing. A SIP building envelope has minimal thermal bridging and delivers excellent airtightness, which lends itself ideally to LEED and net-zero-ready building standards.

R-Values

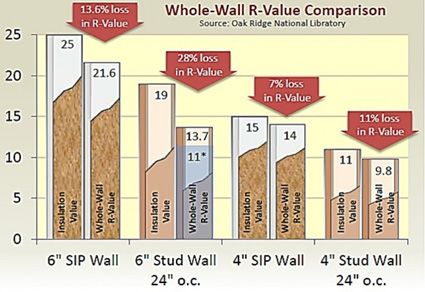

Insulation is one of the key components of any energy-efficient home or commercial building. With heating and cooling accounting for 50 percent of energy use in the average home, good insulation saves thousands of dollars in utility bills over the life of a home.

Insulation is rated by R-value, which measures a material’s thermal resistance. An insulating material with a higher R-value forms a more effective thermal barrier between the outside temperature and the conditioned space inside the home. Research funded by the U.S. Department of Energy confirms that SIP walls provide more R-value than same-sized stud walls.

Healthier Indoor Air Quality

A SIP home or commercial building allows better control over indoor air quality because the airtight building envelope limits incoming air to controlled ventilation which filters out contaminants and allergens. The SIP envelope doesn’t have the voids or thermal bridging of conventional stick framing that can cause condensation leading to potentially hazardous mould, mildew or rot.

Indoor Air Quality

A SIP home or commercial building allows for better control over indoor air quality because the airtight building envelope limits incoming air to controlled ventilation. Controlled ventilation filters out contaminants and allergens, and also allows for incoming air to be dehumidified, reducing the possibility for mold growth. This ventilation system is especially important in regions experiencing seasonal wildfire smoke as well as high precipitation, humid climates.

There are a variety of ventilation strategies that can be employed to provide fresh air to airtight homes. These vary by climate, but most are relatively inexpensive and operate on automatic control systems without the need for homeowner action.

Sustainability Credentials

SIPs are highly energy-efficient and therefore contribute positively to the environment by reducing CO2 levels. They also use significantly less energy during the manufacturing process compared to traditional construction methods and have lower embodied energy than traditional construction materials, such as steel, concrete and masonry.

SIPs Sustainability

Structural insulated panels are one of the most environmentally responsible building systems available. A SIP building envelope provides continuous insulation, is extremely airtight, allows for better control over indoor air quality, reduces construction waste, and helps save natural resources. Life cycle analysis has shown that SIP homes have a tremendous positive environmental impact by reducing energy use and greenhouse gas emissions throughout the home’s life cycle.

Faster Construction With Less Labour

SIP walls and roofs are designed and precisely manufactured offsite. This allows the building to be assembled onsite quickly and made watertight in a matter of days. This reduces costs such as project management, scaffolding, framing labour and much more. A BASF time-motion study confirmed that SIP panels reduce jobsite labour needs by 55%.

The Proof is In The Savings

The SIPs True Value Bidding Tool helps demonstrate the added value of a SIP project with every lead that your business encounters. It’s an easy and free way to elaborate on the additional value included in a SIP structure that conveys more than energy performance – it demonstrates the true cost associated with project and the real savings in choosing SIPs.